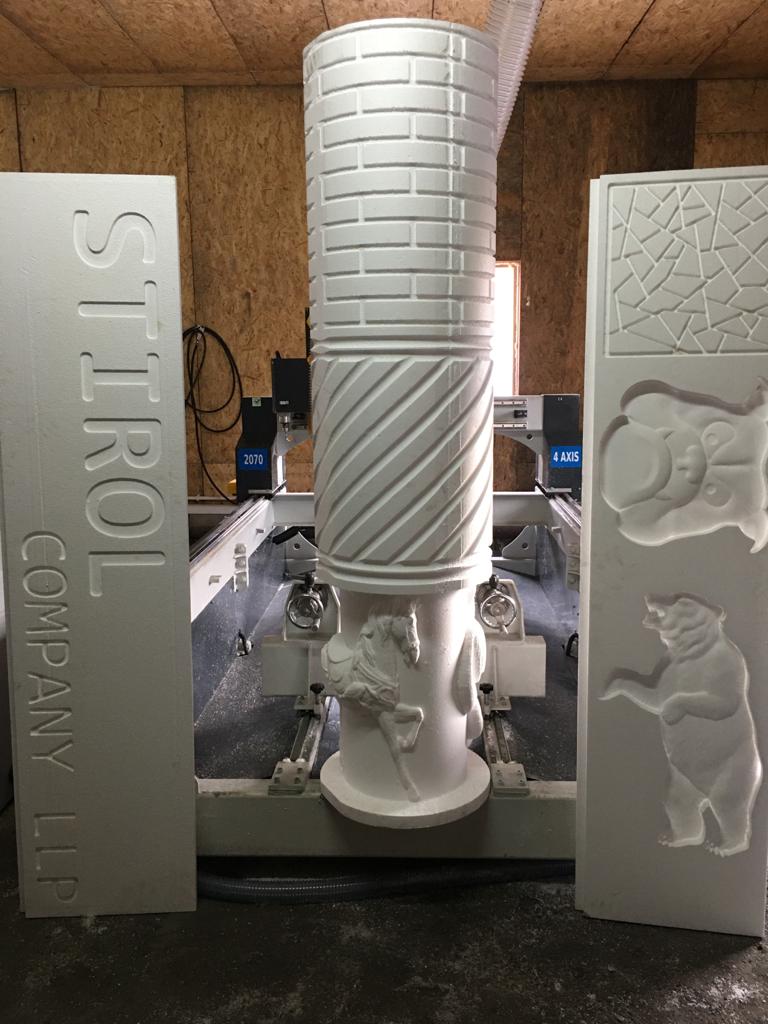

Pac 2070 4 Axis Cnc Router

PAC 2070 SERIES CNC ROUTER

Pac 2070 series 4D CNC routers can process more complex shapes with its additional 4th axis, like engraving a text on a colon or a face, when compared to 3D machines.

Other common products that could be processed on this machine are colon heads, colon bases, statues, moulds for modelling and similar.

The materials, suitable for processing, are EPS or XPS foams, wood, MDF, plastics and composite materials.

This machine has detachable vacuum working table, which can be used to work on parts that do not require 4th axis.

The machine has two 4 kW 18.000 rpm ER32 spindle motors, which allows to work on two parts simultaneously.

All of the working axes of Pac 2070 series 4D CNC router have servo motors and Planet brand reducers.

Y-axis has two Gantry brand motors, on left and right sides.

Optionally, it is possible to add a 2.500 m3/h dust collecting unit.

AREAS OF USE:

Mould modelling

Advertisement and promotion products

Furniture parts production

TECHNICAL FEATURES

|

Net Working Space |

X: 2000mm Y: 700mm Z: 350mm 4th axis:Ø600 |

|

Product Dimensions |

Flat working table: 2000mm x 700mm x 300mm Rotating axis (2 pieces): Cylinder: Ø600mm, Length: 2000mm Rectangular:420mm x 420mm, Length: 2000mm |

|

Body Construction |

Milled steel body |

|

Guideway System |

25 mm Linear guideway and carrier |

|

Drive System |

X: M2 Helical rack Y: M2 Helical rack Z: 2005 Ball screw |

|

Working Table |

Flat working table: 30 MDF vacuum table Rotating axis: 2 meter adjustable shaft |

|

Spindle Motor |

4 kW 18.000 rpm |

|

Axis Motors |

750 W AC Servo + Planet brand reducer |

|

Control System |

DSP CNC control unit |

|

Other Feautres |

Central greasing system 2.500 m3/h dust collecting unit (optional) Vacuum pump |

.jpg)